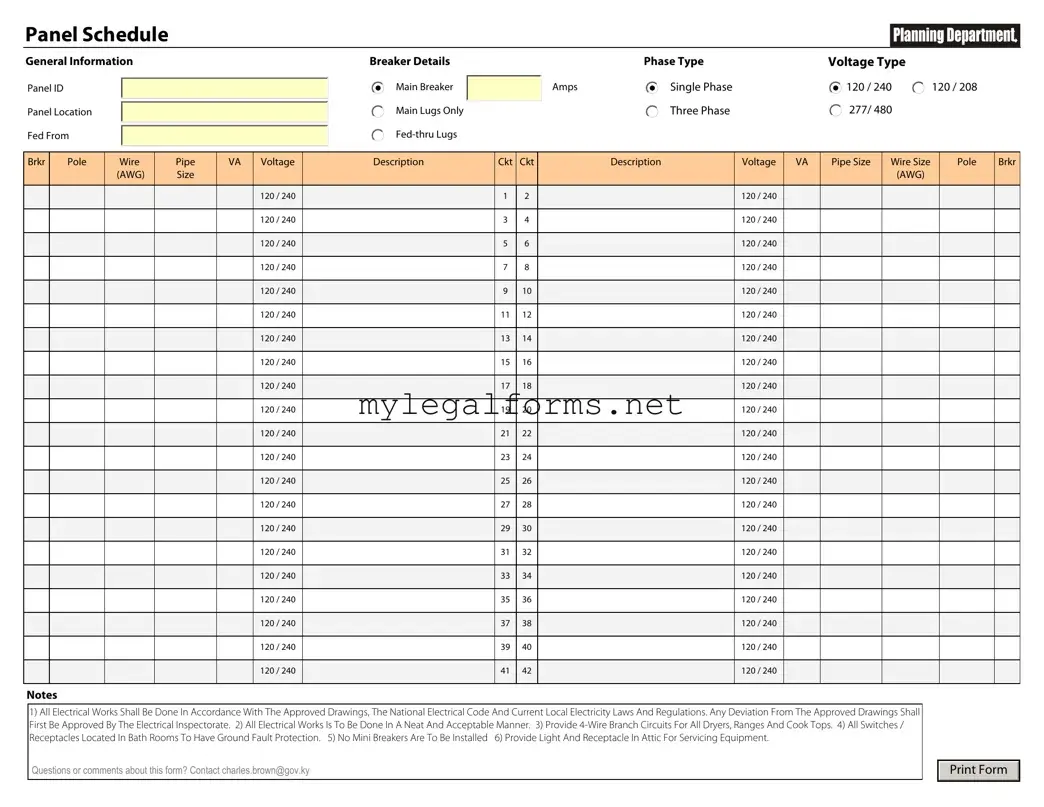

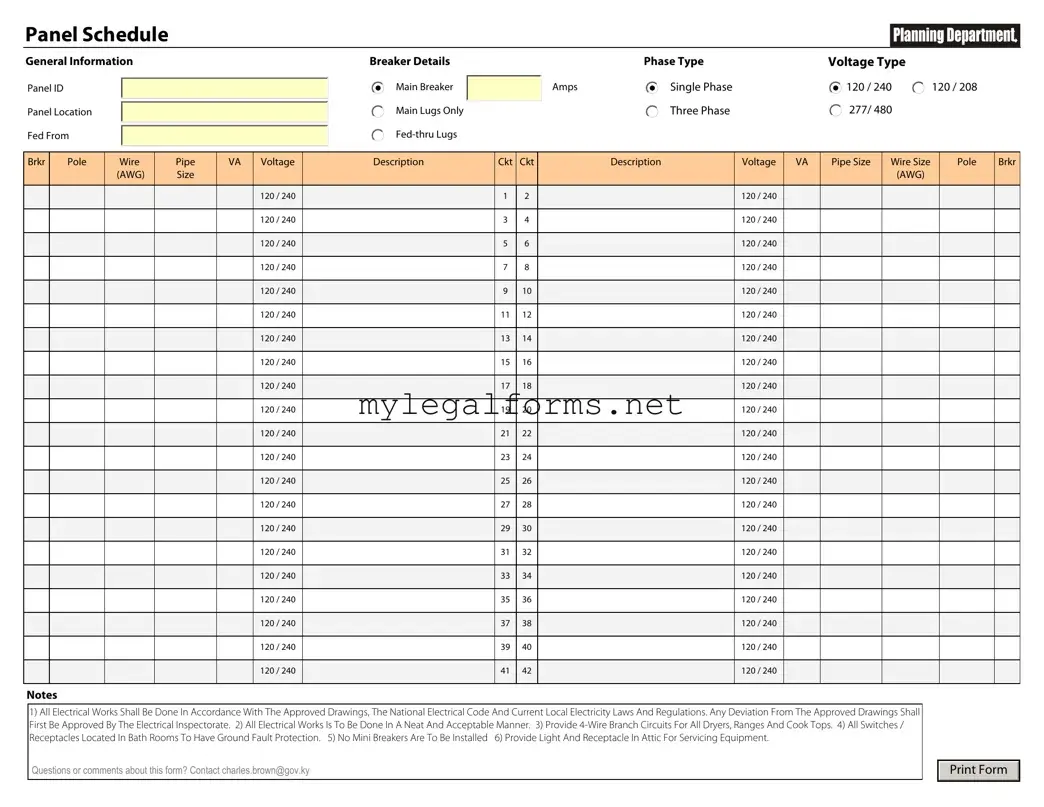

Completing the Electrical Panel Schedule form can be a straightforward task, yet many individuals encounter common pitfalls that can lead to confusion and errors. One prevalent mistake is failing to accurately identify the panel's location. Each panel should be clearly labeled with its specific location within the building. Neglecting to do so can result in difficulties during installation or maintenance.

Another frequent error involves overlooking the proper labeling of circuits. Each circuit should be distinctly marked to ensure that anyone working on the panel can easily identify its purpose. When labels are vague or inconsistent, it can lead to significant safety hazards and operational inefficiencies.

Inaccurate load calculations represent a critical mistake that can have serious implications. It's essential to calculate the load for each circuit correctly to avoid overloading the panel. If the load is underestimated, it could lead to equipment failure or even electrical fires.

People often forget to include all necessary information regarding the type of equipment connected to each circuit. This includes details about the voltage and amperage requirements. Without this information, the panel may not function as intended, leading to potential disruptions in service.

Another common oversight is neglecting to update the panel schedule when changes occur. Whether new circuits are added or existing ones are modified, it is vital to keep the schedule current. Failing to do so can create confusion and increase the risk of accidents.

Some individuals mistakenly use inconsistent units of measurement. For example, mixing volts and amps without clear distinction can lead to misunderstandings. Consistency in measurement units is crucial for clarity and accuracy in the schedule.

Additionally, people often skip the review process entirely. Taking the time to double-check the completed form can catch errors before they become problematic. A thorough review can help identify mistakes that may have been overlooked during the initial filling.

Another error occurs when individuals do not consult relevant codes and regulations. Adhering to local electrical codes is essential for safety and compliance. Ignoring these regulations can result in fines or the need for costly corrections later on.

Finally, a lack of communication with other team members can lead to misunderstandings. Ensuring that everyone involved in the project is on the same page regarding the panel schedule can prevent future complications. Clear communication fosters collaboration and enhances overall project efficiency.