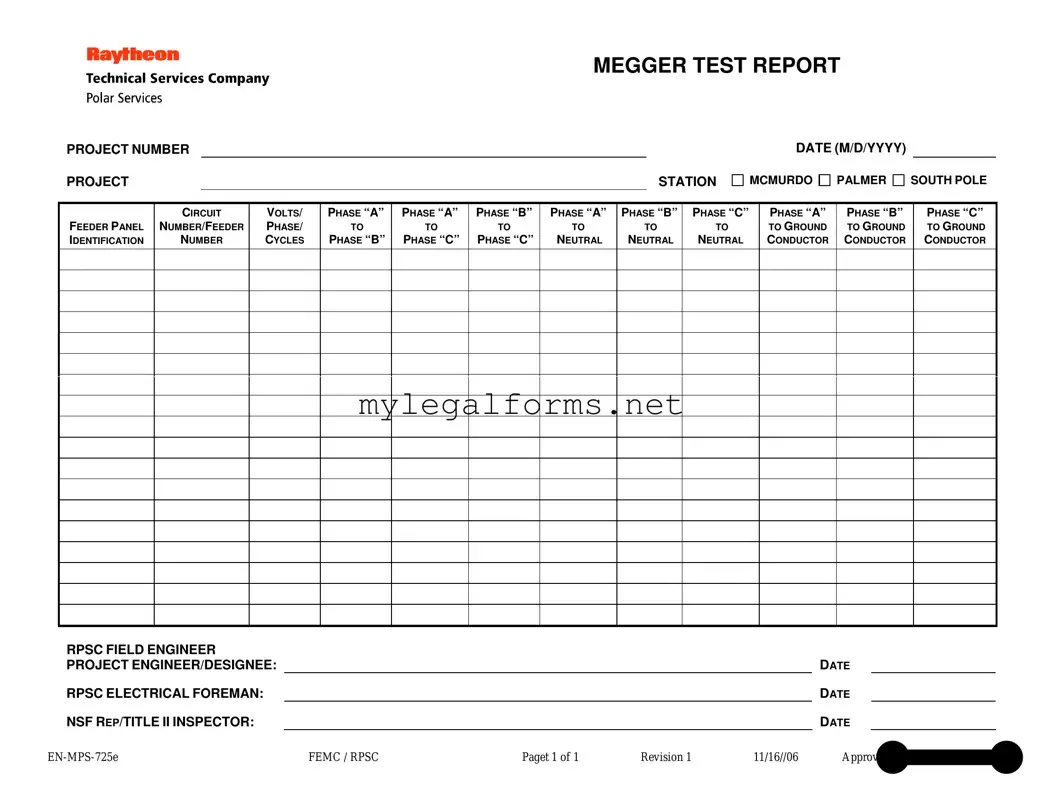

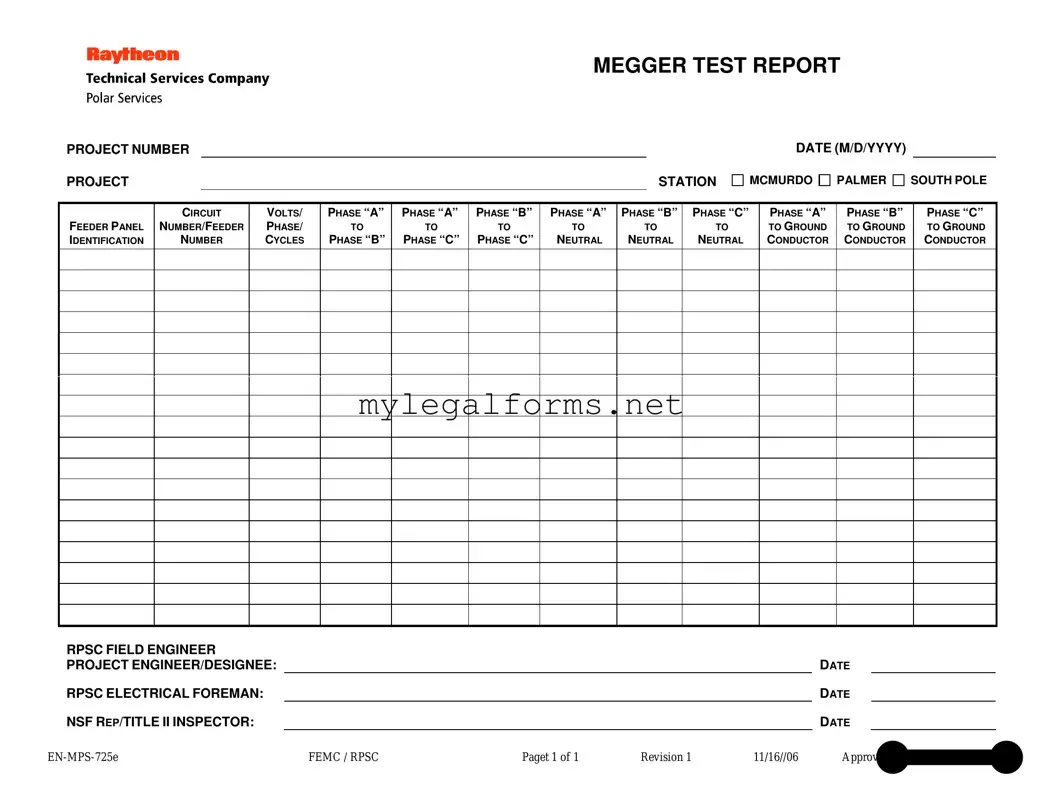

Megger Test Template

The Megger Test form is a crucial document used to record the results of insulation resistance testing in electrical systems. This form captures essential data, including project details, circuit identification, and voltage readings across various phases and neutral connections. By ensuring accurate documentation, the Megger Test form helps maintain safety and compliance in electrical installations.

Launch Megger Test Editor

Megger Test Template

Launch Megger Test Editor

Launch Megger Test Editor

or

⇓ PDF Form

Complete the form at your pace — fast

Finish your Megger Test online and download the final version.

PALMER

PALMER

SOUTH POLE

SOUTH POLE