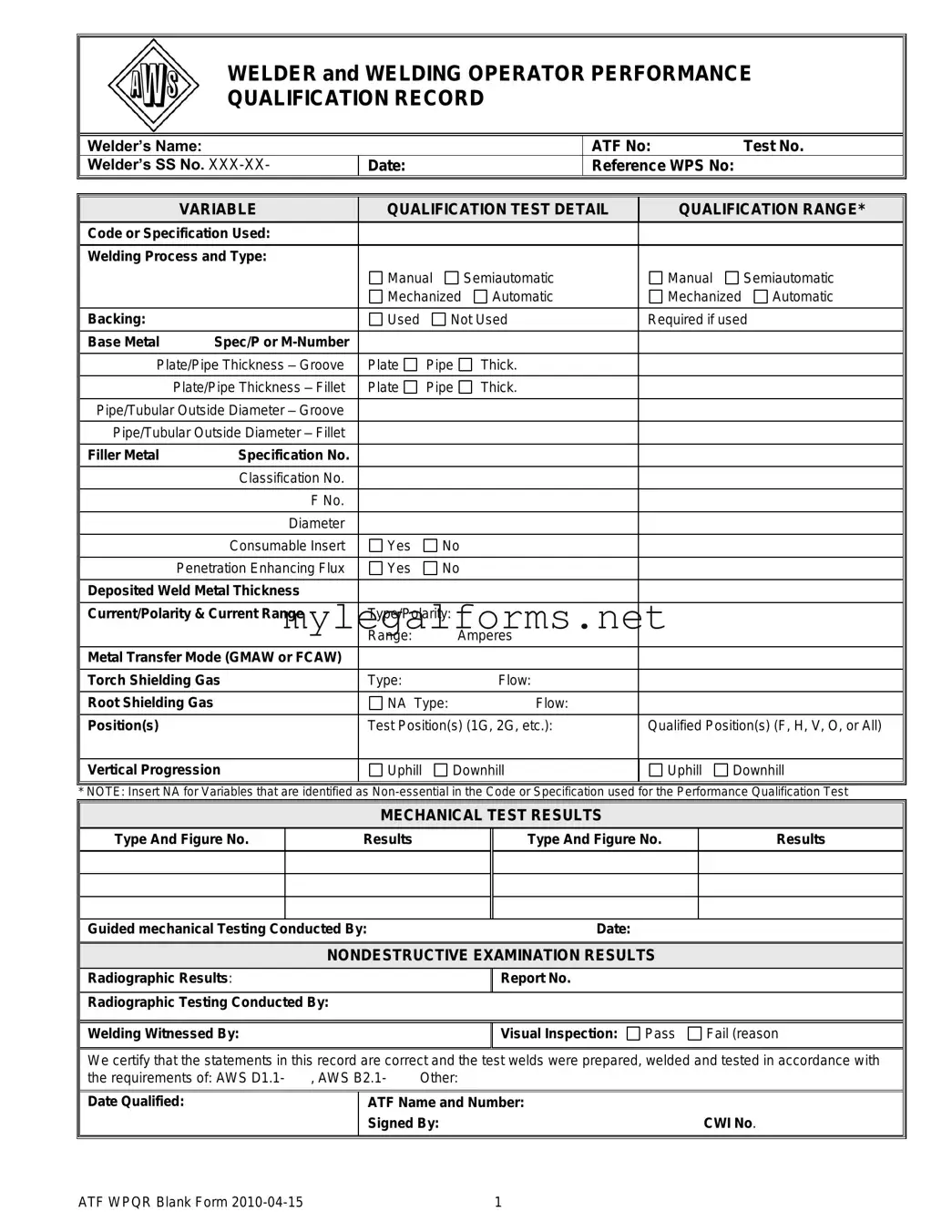

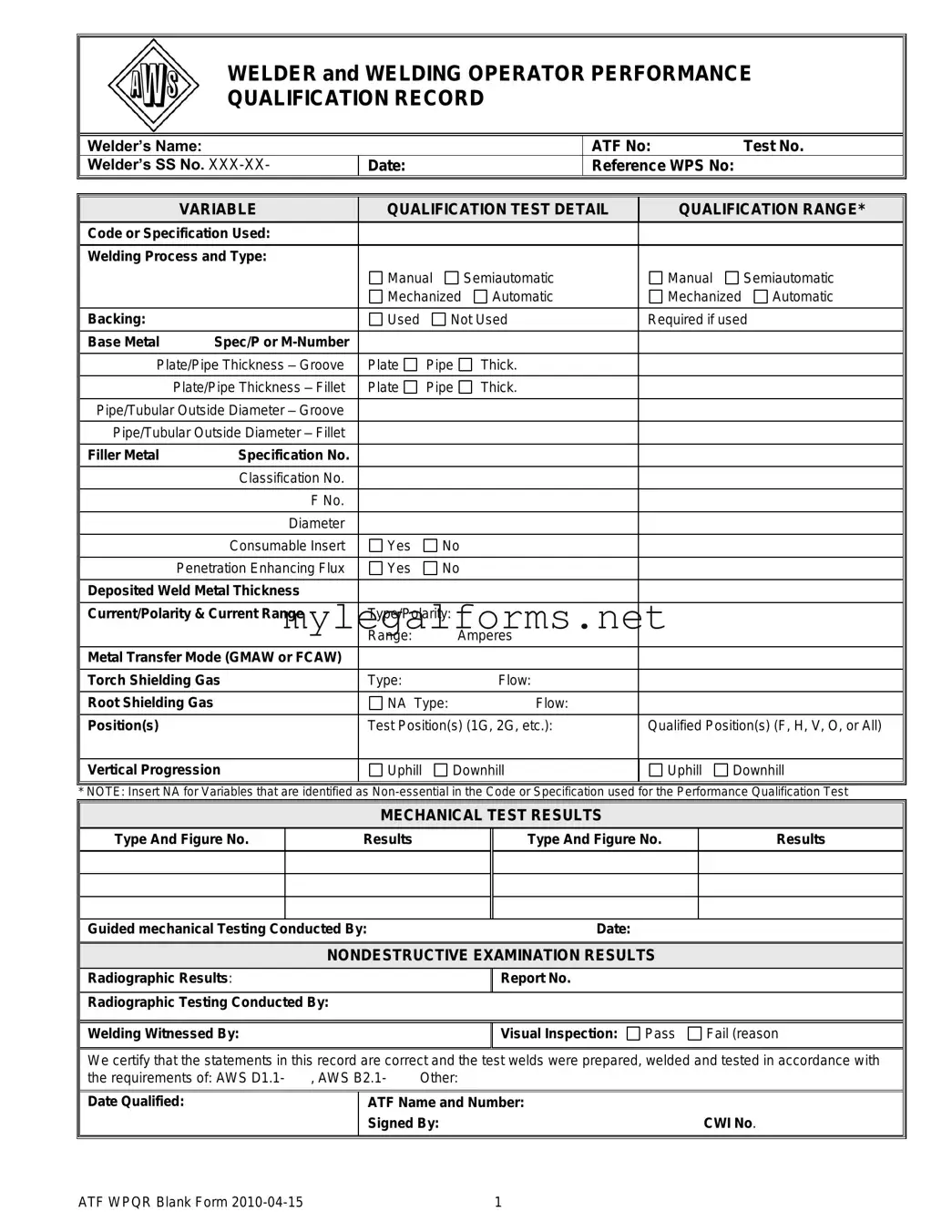

Welder Performance Qualification Record Template

The Welder Performance Qualification Record form is a crucial document that verifies a welder's skills and qualifications. This record captures essential details about the welder, the tests they’ve completed, and the results of those tests. By maintaining accurate and thorough documentation, employers can ensure that their welders meet industry standards and safety requirements.

Launch Welder Performance Qualification Record Editor

Welder Performance Qualification Record Template

Launch Welder Performance Qualification Record Editor

Launch Welder Performance Qualification Record Editor

or

⇓ PDF Form

Complete the form at your pace — fast

Finish your Welder Performance Qualification Record online and download the final version.